Efficient Control Solution for Air Conditioning External Fan Based on Advanced ADP16F03

In a high-temperature environment of 35°C+, air conditioning is the core equipment to ensure indoor comfort, and the need for rapid cooling during the day and precise temperature control at night both put forward high requirements for the dynamic adjustment ability of the system. As the core of energy conversion and heat dissipation of inverter air conditioners, the control accuracy of outdoor fans directly determines the energy efficiency, temperature control stability and operation reliability of the system.

Frequency conversion technology improves the energy efficiency of the compressor frequency and the speed of the external fan by more than 30% compared with the traditional fixed frequency, but it puts forward strict requirements for real-time processing, multi-dimensional signal interaction and environmental adaptability of the core control unit. As the core control unit of the outdoor unit, the DSP ADP16F03 the core of the outdoor unit has built a refined collaborative control system with its integrated high-performance processing architecture and multi-dimensional signal interaction capabilities.

Hardware performance: The core architecture that supports precision control

ADP16F03 is equipped with a 16-bit fixed-point DSP core (main frequency 150MHz, Harvard bus structure), integrated operation acceleration unit (supports division, square opening and Parker transform and other instructions), efficiently runs a single-resistive non-inductive FOC algorithm, realizes microsecond-level motor control key operations, and provides a strong computing power guarantee for the collaborative adjustment of the compressor and external fan.

At the signal acquisition and execution level, the chip has a built-in 12-bit ADC module (slew rate 1MSPS), supports 16-channel synchronous sampling (including temperature sensor channels), and captures multi-dimensional signals such as indoor temperature difference, condenser temperature and pressure, bus current and phase current in real time. The EM1 event manager provides 8 PWM outputs (of which 6 are adapted to the motor drive in complementary mode), combined with the channel sequencer to accurately configure sampling and interrupt trigger timing, and constructs a closed-loop control link of "signal acquisition-algorithm operation-drive output" to ensure that the delay of compressor frequency and fan speed adjustment is ≤ 10ms.

In terms of hardware integration, the chip integrates 1 operational amplifier (OP) and 3 programmable gain amplifiers (PGA), which can directly amplify bus current and phase current signals without external circuits. The three voltage comparators support back electromotive force (BEMF) detection, and the single-resistive inductive FOC algorithm eliminates the need for Hall sensors, thereby reducing hardware costs, reducing wiring nodes, and enhancing system immunity.

Scheme features: technical optimization for complex scenarios

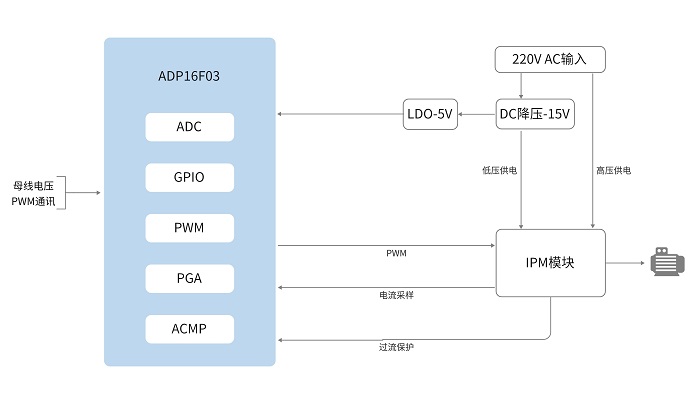

▲Block diagram of the scheme

Dynamic adjustment accuracy: Using the self-developed revolution tracking algorithm and pre-positioning closed-loop starting technology, the adjustment error of the external fan in the range of 0-1500rpm is ≤±5rpm, and the starting success rate under downwind conditions reaches 100%, which solves the problem of speed fluctuation under strong wind interference. The compressor frequency adjustment supports 0.5Hz steps, and with the feedback of the room temperature difference, the temperature control accuracy of ±0.3°C can be achieved.

Protection mechanism: Through 2 configurable voltage comparators and DAC to form upper and lower limit protection circuits, combined with 3 sets of independent digital delay filter units, multi-dimensional protection such as over-voltage (≥264V), under-voltage (≤180V), over-current (≥8A), phase loss, and blocking rotation is realized, and the response time is ≤ 50μs to avoid device damage under abnormal working conditions.

Environmental adaptability: The chip has 2000V ESD protection (HBM standard) and MSL3 moisture sensitivity rating, and can operate stably in the ambient temperature range of -40°C~125°C. It supports LQFP48/LQFP32/VQFN48/VQFN32 packaging forms, adapts to the layout requirements of outdoor unit PCBs of different sizes, and meets the driving scenarios of PMSM motors within 150W.

Technical support

Jinxin Electronics can provide customers with the above scheme schematics, PCB reference board diagrams, source code, and software and hardware development technical support corresponding to the scheme, if you need to know more about the details of the solution, please call 0731-88731027.

CN

CN

EN

EN