Media Focus | Domestic Manufacturers, Striving for This Chip

This article is reprinted from Semiconductor Industry Observation.

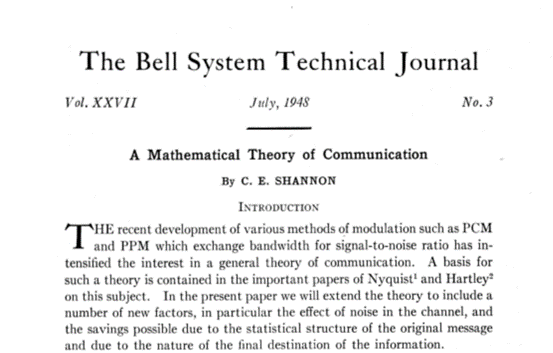

If the birth of the first digital computer, ENIAC, in 1946 marked the beginning of the digital age, then 1948 can be called the first year of DSP (digital signal processing). Because that year, Claude Shannon of Bell Labs published his landmark paper, A Mathematical Theory of Communication, which clearly articulated the relationship between achievable bit rates, channel bandwidth, and signal-to-noise ratios.

It can be said that Xiang Nong's paper has opened up a new era. But when it comes to hardware, there are still many years left before the first DSP chip is launched. Because even the most basic IC will take 10 years to be invented by TI's Jack Kilby. But after its subsequent debut, DSP has been popular in the market for decades.

Professional players, better than business players

The so-called DSP, according to Wikipedia, is a specialized microprocessor chip with an architecture optimized for the operational needs of digital signal processing. In real-world applications, the goal of DSPs is typically to measure, filter, or compress a continuous real-world analog signal. While most general-purpose microprocessors can successfully execute digital signal processing algorithms, they may not be able to keep up with this processing in real time and continuously, making DSPs the preferred choice for applications with such demands.

China's first batch of technical experts engaged in DSP research bluntly said that the reason why DSP can take the lead in many fields is because "professional players are always better than business players". To understand this sentence, we must first start with the processor architecture.

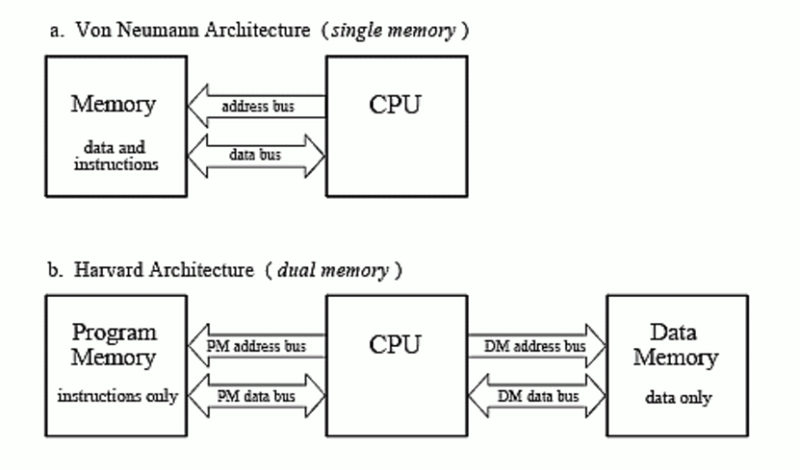

At present, although an architecture called in-memory computing has been very popular in recent years, the processor architectures we are more familiar with are basically von Neumann architecture and Harvard architecture. Among them, the von Neumann structure processor uses the same memory and transmits it through the same bus; The Harvard structure is a memory structure that separates the program instruction store from the data store.

Specific to DSP, according to Gene Frantz, former chief scientist at TI and founder of DSP products, in an article titled "Digital signal processor trends" published in 2000, the original DSP design also borrowed another idea from early computer research. For example, the first microprocessors, like the computer central processing unit before them, used the von Neumann architecture with a single bus and a unified address space for data and instructions.

However, DSP designers grabbed the Harvard architecture with independent buses, but they used the idea in a novel way. In addition to adding instruction buses, designers have provided separate buses for each multiplicative cumulative operand. As a result, data and instructions can be loaded and a full multiplicative accumulation can be performed during each cycle. Because designers accepted the value of a unified address space, they did not separate instructions from data in primary memory, although caching schemes introduced later often kept small amounts of data and code separately in on-chip memory.

Since then, this improved Harvard architecture has been an integral part of DSP, although today's architecture may contain many features that original computer researchers could not have imagined in their wildest fantasies. So while DSPs are similar to RISC engines in some ways, they are fundamentally different in others.

In conclusion, since many mathematical functions are useful for converting and manipulating analog signals in the digital realm, a machine capable of performing these mathematical functions efficiently will be invaluable as a DSP. As a result, some microprocessor architects designed processors around hardware specifically designed to perform multiplicative and cumulative functions, and DSPs were born.

Essentially, DSPs are designed for numbers. As a pure pedigree dedicated field processor, DSP has excellent professional capabilities, high instruction execution efficiency in applicable fields, low power consumption, and peripheral supporting peripheral resources are also professional and efficient, and the overall chip cost is highly competitive. Thanks to these advantages, audio, video signal processing, communication, real-time control, motion control, motor control, new energy, automotive electronics and digital power supply have also become loyal followers of DSP over the past few years.

The heroes compete for hegemony, and the family is dominant

Where it is profitable, there must be competition, which is an eternal truth, and this is of course also present in the DSP market. At the beginning of the article, we talked about that there is still a very long time difference between digital signal processing and the emergence of real digital signal processors.

However, many manufacturers have rushed to the digital signal processor market.

According to the data, Bell Labs developed Adaptive Predictive Coding (APC) in 1967, which made it possible to obtain fairly good audio in a 4.8kbps bit stream; Intel introduced the first commercial microprocessor, the 4004, in 1971, capable of multiplication and addition, but its relatively weak ALU and bit width limited its development; TRW successfully created and sold a 16×16-bit single-chip digital multiplier MPY016H in 1976, but because it could not do "addition" and needed an additional IC to complete it, the chip was not an innocent DSP.

After the launch of various types of chips and products such as the TMS320 DSP in 1982, the digital signal processor (DSP) we are now familiar with finally officially came to the forefront, and it has been new for a long time.

In a way, the TMS 320 may not really be called the first DSP, because before that, Intel launched the 2920 analog signal processor and 8088 microprocessor aimed at the same goal, and AT&T showed the DSP-1; NEC also has the μPD7720. After TI, there are also manufacturers such as Motorola, Philips, ADI, NXP, Cirrus Logic and CEVA, as well as Tesilica, which have also performed well in their respective markets.

For example, Analog Devices' Tiger Shark series has a leading position in the audio field; Embedded processors such as CEVA and Tesilica also have unique profound profound knowledge in the field of embedded applications. Among them, TI is a company that has to be mentioned among DSP suppliers. Thanks to its leading product design and targeted investment, TI has almost single-handedly led DSP practitioners to hold this position in the past few decades.

The C2000 series, in particular, has become a monument in the field of DSP.

According to relevant information, the predecessor of TI's first-generation C2000 can be traced back to a DSP for hard drives they developed in 1995. In 1997, TI's first 16-bit dedicated chip for motor control, the F24x DSP, was introduced, and although it now seems that the product is simple, with only 20MHz main frequency, with a 10-bit ADC and 3-phase PWM, the chip still quickly gained a foothold in the digital motor control market. Later, TI launched new chips in response to market demand, invested in market education, and eventually established the company's position in the DSP market.

In the view of senior industry practitioners, the reason why TI has been able to dominate the market in the DSP market for many years is first of all due to its leadership in product design. Taking the C2000 series as an example, this series of chips that have been around for more than 20 years has many advantages:

On the one hand, the core of this series of chips is powerful: it supports 2-4 16*16 hardware multipliers, which can perform multiplication operations in a single cycle; A single instruction can drive 2-3 cores to perform parts at the same time; Scalable support for hardware acceleration units such as floating point and trigonometric functions; With powerful compilation tools and library function support, the instruction execution efficiency is more than 3 times that of general-purpose MCUs.

On the other hand, from the perspective of chip system architecture, the C2000 series can be said to be born for real-time signal processing. Its high-precision, high-speed data acquisition, pre-processing capabilities, digital filtering of IO channel input signals, and enhanced interrupt control system designed for real-time response of interrupt signals provide a highly reliable data source for the powerful digital processing of the core. The floating-point acceleration operation of the algorithm executed by the on-chip CLA coprocessor can effectively reduce the load on the main core and improve the response speed of the system. Through the combination of on-chip CLB and X-BAR, the chip has hardware programmability, greatly reducing the number of peripheral logic devices.

In addition, the system peripherals that support 100ps high-precision eCAP and high-precision PWM enable the chip to achieve more accurate control capabilities, and to exert the excellent performance of the chip in the control case of using new GaN and SiC power drivers.

Finally, TI attaches great importance to maintaining the leading position of C2000 DSP products, and continuously launching new products by digging deep into the needs and pain points of industry customers is also another important driving force for TI to stand where it is today. For TI, years of university education cooperation are also key to gaining recognition in the market, and this is no exception in the DSP market.

It is precisely because of the considerable revenue brought by TI DSP's dominance and the opportunities brought by the market that global chip manufacturers are eyeing the market they are targeting, and the Chinese market players are no exception.

Going forward and successively, local manufacturers are dead

As for who was the first to invest in the research and development of domestic DSP, the author has not yet studied. However, according to relevant data, since 1985, since the National Application-Specific Integrated Circuit Design Engineering Technology Research Center, there have been a number of manufacturers including CLP 14, Quantum Micro, Hunan Jinxin, Jiangsu Hongyun, Zhongke Benyuan and Zhongke Haoxin from scientific research and independent equipment customization needs, invested in the wave of DSP localization.

Although it has gone through rounds of research, domestic DSPs are still not widely recognized by manufacturers in the market, and the giants are still those giants. When asked why this is still the case, the senior DSP research expert said:

First of all, objectively speaking, most of the application scenarios of DSP are industrial customers, compared with consumer customers, industrial customers have significantly higher requirements for product reliability and performance indicators than consumer customers, and the entry threshold of the industrial market is much higher and not easy to enter.

Secondly, the long life cycle of industrial products leads to a relatively long introduction cycle of DSP products, and it is necessary to be prepared for a protracted battle. Third, the change in the industrial market's perception of domestic chips requires a process, and the formation of domestic DSP chips to form a brand and reputation also needs to pass the test of the market.

In the process of maturing domestic DSP products, if there is a problem of product quality batch, or the product cost is too high compared to the opponent, or the solution lacks advantages in cross-border competition with MCU, it is easy to lead to the localization of DSP products.

There is no doubt that the domestic substitution of DSP will not be an easy task. However, affected by the current international competition situation, local developers urgently need DSP chips that can help create highly competitive products with cost reduction advantages, supply chain security guarantees, and assistance in creating highly competitive products. In other words, the development of domestic DSP is the only choice.

As a result, domestic manufacturers continue to knock on DSP. Taking Hunan Jinxin as an example, because the localization of products started early, the company has been verified by mass use by industrial and automotive users, with stable quality and strong supply chain guarantee capabilities; Recently, the speed of new product launch, cost-effectiveness, and timely product service have established a good customer reputation. Even so, there is still a huge gap compared with the overall strength of foreign friends.

In addition to building a DSP architecture, domestic manufacturers are also exploring RISC-V to break the existing competitive situation of DSP. In the eyes of industry practitioners, this is a beneficial attempt, but it is still focused on the middle and low end, and there is still a lot of software porting work to be done. If it wants to play a more important role in the DSP market in the future, more work needs to be done on the expansion of the RISC-V instruction set.

It is undeniable that after years of exploration, domestic DSPs have also made some achievements in substitution. This is due to our import from the low-cost market; on the other hand, thanks to our rich IC engineer resources; In addition, being able to flexibly customize products and services for customers is also an important means for domestic DSP manufacturers to tackle tough problems; More importantly, in recent years, China's dominance in new industries such as new energy vehicles and energy storage has created new domestic opportunities for local chip suppliers.

But we are far from the time to celebrate. Because as manufacturers such as TI bring DSP into the era of multi-core heterogeneity, it is more difficult to replace. In terms of hardware, in addition to the need for kernel replacement, it is also necessary to do a lot of compatibility design in terms of system architecture and peripheral resource matching; In terms of software, a lot of effort needs to be invested in software compatibility to achieve the goal of basic compatibility.

As for the future, DSP will continue to evolve from three aspects: technology, product and market. From a technical point of view, DSP will continue to proliferate, disappear boundaries, and be ubiquitous; From a product perspective, DSP will continue to evolve, innovate, and integrate AI, FPGA GPU and other technologies into DSP products; From a market perspective, in mid-to-high-end embedded applications or specific fields, DSP will maintain and expand its market share because of its professional performance of chips.

It can be seen that the "localization" of DSP also needs to change over time. Localization is short-term, localization is long-term, and the focus on DSP chips will soon develop from localization to higher-performance DSP inside customer-customized SOC chips.

In 2012, on the 30th anniversary of TI DSP, Gene Frantz said in an IEEE article: "Some people may think it's strange that DSP as a product goes from being worthless to creating billions of dollars in value every year and then disappearing. But it was indeed the beginning of good news. Because it has not disappeared, it is just integrated into every digital processing system. He also pointed out: "There will always be new attractive signals, and there will always be a need to process signals." ”

"Judging from the changes that DSP technology has brought to the world, we are only enjoying the skin now." Gene Frantz said so at the time. In the author's opinion, this sentence is also applicable at the moment.

In other words, domestic DSPs have a lot to offer.

CN

CN

EN

EN