Talking about the high-performance electric drill control board scheme of Jinxin Electronics

In recent years, the global power tool market has accelerated its explosion, and the application scenarios have been continuously enriched. Portable drills equipped with lithium batteries and brushless motors have quickly occupied a large market share of electric drills with their advantages of light weight, high torque, and no power supply restrictions.

BLDC motor is DC brushless motor, which has a series of advantages such as low loss, high efficiency, long life, low noise, reliable operation, and easy maintenance, which fully meets the increasingly high requirements of energy conservation and consumption reduction, intelligent control, and user experience in the terminal application field. The special chip for motor drive control is the heart of BLDC motor control system, and with the current popularity of portable devices, Internet of Things and 5G applications, the requirements for high precision, miniaturization, high integration, and low power consumption of motor drive are also getting higher and higher. Jinxin Electronics can provide a cost-effective electric drill control board solution based on the company's ADM16x series DSP as the main control chip.

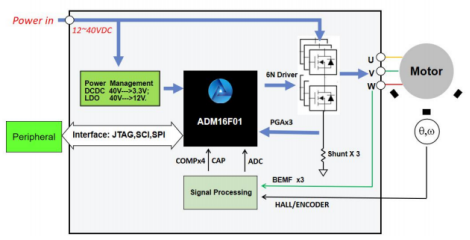

The ADM16x devices offer an enhanced DSP architecture design that enables low power consumption and high-performance processing power at a low cost, integrating several advanced peripherals optimized for digital motor and motion control applications to provide a true single-chip DSP controller. When compatible with existing DSP controller device code, the ADM16x provides higher processing performance and a higher level of peripheral integration.

The ADM16x is a highly integrated, high-performance BLDC/PMSM controller with 6 integrated NMOSPre-Drivers, operational amplifiers, PGAs, comparators, high-speed ADCs, SCIs, SPIs, and other modules. At the same time, it adopts a high-performance 16-bit CPU with embedded 32Kx16-bit Flash, 512x16-bit ROM, and a maximum operating frequency of 40MHZ, which can meet the application requirements of high-performance brushless motor control and simplify system costs.

▲Typical application diagram

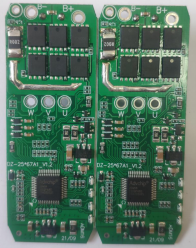

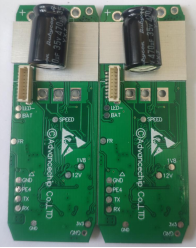

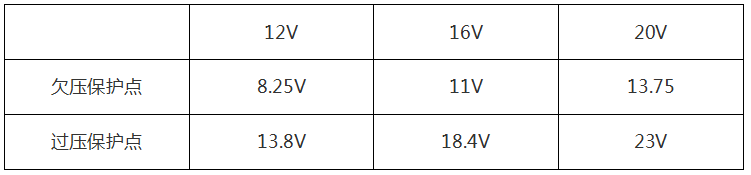

This electric drill scheme is designed with two types of plates according to the actual assembly needs, namely the notched square plate (hereinafter referred to as the square plate) and the notched angle strip plate (hereinafter referred to as the strip plate), of which the square plate samples the 20V power supply system, and the strip plate can be applied to the 12V, 16V and 20V power supply systems. The motor speed range is 200~23000rpm, and the strip plate is also equipped with 3 LED power indicators.

▲The front view of the board

▲ Back view of the board

●Compatible with 12V, 16V, and 20V power supply motors

●Motor speed range: 0~23000 rpm

● Maximum torque: 40N.m

●A variety of protection measures: over-current protection, reversal protection, short circuit protection, over-voltage protection, under-voltage protection, blocking protection, battery over-temperature protection, MOS tube over-temperature protection, etc.

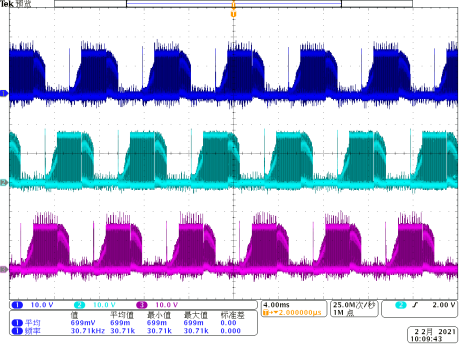

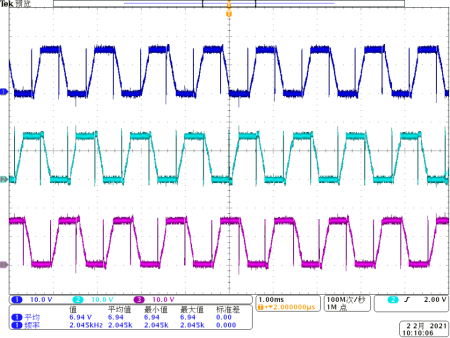

This scheme uses a non-inductive square wave algorithm to trigger continuous power supply through a button, and the ADC sampling button controls the rotation of the motor according to the PWM wave output corresponding duty cycle according to the pressure degree, and the ADC also controls the normal operation of the motor with the back EMF of the sampling motor. In addition to motor control, the ADC monitors other currents and voltages during operation, and displays the current status through status lights. The stable start output torque is large, the rotation direction can be freely switched by the switch, and the rotation is stopped immediately after releasing the button, and it is equipped with lighting LED and 4S delayed power-off function, which is convenient for checking the punching effect in low-light environments.

▲Tap the motor running waveform

▲Re-press the motor running waveform

CN

CN

EN

EN